Hello, have you ever thought about sourcing from China?

Let’s say you are a small business owner with great ambitions, preparing to take a specialized product into the market. You have an idea, passion, and perhaps a prototype. The next thing you will wonder, as do most entrepreneurs, is where to acquire it made, and at a price that won’t break the bank. Most entrepreneurs think of China, the manufacturing juggernaut – and rightfully so. It has long been the choice for every entrepreneurial venture- big or small. From the sneakers on your feet to the phone in your pocket, the odds are that something in your vicinity was ultimately made in China.

So what are we talking about? Well, sourcing from China can be a game changer for your business – if you know how to win the game. It’s not just about cheap labor or low costs – although that’s a benefit too. It’s about accessing a massive web of factories, suppliers and providers in order to create your vision in a much shorter time frame. But there are obstacles, pain points, and a learning curve. That’s the purpose of this guide – to help you along the journey of sourcing from China. Whether this is your first time or you are looking to improve your process, we will do this together.

China as a manufacturing powerhouse isn’t an accident. In the late ‘70s they opened themselves to foreign investment – and by the late ‘90s they were producing anything and everything. China isn’t just working on your low-end t-shirts anymore. They are also working with your high-tech devices, and developing customized solutions for companies. For business owners like you this means opportunity and smart business. If you can figure out how to run through the maze we call China you can save a ton of money and grow faster. I have been in the small business game long enough to know the excitement of bringing your idea to life without needing to smudge your savings.

China has that potential, but you need to look before you leap; you don’t want to jump into a pool without checking how deep the water is first. Stay with me through this guide and I will show you both the opportunities and pitfalls of sourcing from China. Once we finish, you will be equipped with a clear blueprint to determine if sourcing from China is for you. It is not one size fits all, but this may be the push you are looking for. Are you ready to discover what sourcing from China has to offer you? Let’s get into it and find out what exciting opportunities may lie ahead. Ready to go?

Why China? Because it makes sense

Let’s get down to business and make it clear: Most of your decision to manufacture in China and not the US or anywhere else is financial. Sourcing in China will likely save you a considerable amount of money. This matters because labor to produce products and the scale to which an operation is willing to manufacture is a luxury provided by China that is not seen in many other countries. As a small business owner working to get every last penny out of your venture this is essential. Who doesn’t want to keep overhead low while providing value to their customers? Suppose you are manufacturing a specific batch of custom T-shirts. It may cost $10 each to create in the US, but maybe you can get it to $3 or $4 in China. Not only is that money saved; it’s a gift for the budget. Honestly, think of how you could spend that saved money—rebuying ads, changing the designs, or simply not worrying about the prices.

However, it’s not just about saving dollars. China has a crazy amount of products and industries. Need electronics? Hundreds of factories have nothing to do but make them. Textiles/ clothing? Entire cities such as Guangzhou packed full of suppliers ready to make your designs. Furniture, toys, machines, you name it; it exists. It honestly feels like a huge grocery store with limitless options. I have a friend who one time started an e-commerce store to sell nothing but weird home décor. Everything he sourced from China; candle holders, wall art, etc. He was able to build a successful business because he was able to access an array of products. The wide selection allows for exploration without initially committing to a category. If you have an idea for a weird gadget, or want to start a strange clothing line, chances are there is a factory in China ready to do it.

With this variety comes scalability, and if you want to limit your risk and start with a small order, you can, and when you are ready to scale to thousands of units for Black Friday, you can. They can also do that. Recognizing the flexibility of China’s factories, whether you are a startup ordering 100 units, or a retailer ordering 100,000 units is amazing. For business owners looking to grow, the ability to scale is a dream. Have you ever attempted to scale up production of product locally, only to discover that you had suppliers who could only deliver a limited amount? Frustrating, huh? Well, that is less of a concern in China, as you can expand at your own pace, knowing there is production capacity to support you. It’s almost like a safety net of dreams.

Here’s something to consider: China has the mix of resources to make it happen. We’re talking raw materials available whenever you want it, (with in basically a 1-3 day delivery cut-off), immense industrial zones of manufacturers literally packed with operational factories, and supply chains all lined up. Ever heard of Shenzhen? It’s more than just a city, it’s a monster for tech manufacturing. Companies like Apple and Tesla do not source from China by mistake. These companies know China has expertise and capabilities and can get it done. With technology in China continually shifting, you are getting much more than cheap product, you’re getting the result of innovation. Factories in China are adopting automation and smart manufacturing, which means you can access cutting edge products, at half the cost of the Silicon Valley price tag. As a small business, that is amazing access to modern technology for a fraction of the price.

Let’s talk about labor for a moment. Yes, it is true that wages have increased in China over the years; though you can’t expect a cheap-cost forever pay, and they are competitive, in relationship to a western market. Also, you have the added benefit of a skilled labor source, the experience you get is, not just labor, when you hire there. I’ve spoken to business owners, who haven’t been able to wrap their head around how manufacturers in China are able to pick up on a complex designs execution, so quickly. It is like working with people who have done it before and have background knowledge. These people can execute very detailed and complex specifications and can meet very tight timelines, often better than a smaller shop in another country. This adds value to your supply chain expertise.

I would not say there are idyllic situations; there are characteristics that have been amalgamated, and we will think through about them in the near future. For instance, cheap production sometimes can equal the need for greater vigilance over quality, and logistics just do not stop when shipping to the other side of the world. Basically, it can be sluggish when moving products from a factory in Shanghai to a warehouse at your halfway mark on the other side of the globe. But, for the time being, recognize that sourcing from China is an opportunity to gain a competitive advantage that is difficult to replicate. Regardless of whether you are launching a startup or working to expand your already established brand, there is a potential here for success. You are almost too, feeling like you have a secret weapon for your business. Exciting, right? So why not? Let’s dig deeper into your reservations and decide how to use your imagination and come to terms with whatever it may be.

Just a quick note: Have you figured out how many holiday items come from China each year? Think Halloween costumes or Christmas decorations; that’s a cash cow for seasonal retailers. If you can time your orders with Chinese suppliers just right, you can make some serious cash during busy times like a holiday or year-end rally. I once knew a guy who sourced inflatable Santas and made a ton of money in November. Just something to consider as we move forward. But let’s shift gears to the challenges and flip the coin to see what you could tangle with if you’re not careful.

The Other Side: Challenges You Can’t Avoid

Let me be real with you. Sourcing from China can be a challenge. Yes, the price and the assortment can make sourcing products from China sweet. But there are many obstacles to negotiate if you’re not careful. I have witnessed several people go in with stars in their eyes, only to be burned because they couldn’t see pitfalls. Honestly, I’ve been in that same position; thinking it would be easy only to hit a stumbling block. Let me highlight a few of the main challenges you will face, so you’re not surprised later. I mean, knowing these upfront will save you from much pain and discomfort, trust me.

The first challenge is language. Unless you are fluent in Mandarin, it will be really hard to communicate

with suppliers. You will make mistakes, sometimes on critical details like product specifications or delivery times. I recall a colleague who ordered 1,000 units of an item, only for the supplier to think he meant 10,000. That’s a big mistake, and I don’t want to even touch the topic of cultural differences. In China, there is more choice when it comes to the rules of business etiquette than there is in the West. As an example, they may avoid coming right out and saying, “No” because they do not want to lose face. This can lead to confusion. You may think everything is fine when really, you are about to find out that it is not the case. Frustrating? Absolutely. Imagine trying to decipher a figure of speech in a language you do not even understand. The up-front work of creating the bridge takes time, and occasionally the cost of a translator or go-between can be worth it.

I could go on about quality control, or lack thereof, but if you keep your finger on the pulse, quality control is a non-issue here. To be clear, not every supplier seeks to cut corners, but some suppliers use substandard materials, or rush to meet a deadline. Take horror stories I’ve heard of business owners receiving shipments that looked nothing like the samples they approved. Picture it – opening a box full of products you are hyped about, only to discover that they look flimsy, or that they are defective. That’s a punch in the gut – especially if you have customers waiting. One of my friends ordered custom phone cases, and half of them cracked when he opened them. He was left scrambling to find replacements while costing himself a loss. The moral of the story here? You cannot be blindly trusting – you have to be verifying. Quality concerns are not a minor inconvenience as they could destroy your reputation if your customers receive lesser quality products. Even if you end up spending a bit more, you need to create checks and balances. Think about the legal and logistical headaches. Did I mention how many ways to lose your intellectual property when outsourcing from China? You have a great idea? Unless you have an iron-clad contract, chances are you are going to lose it. I’ve seen small businesses loose their edge when a supplier turned right around and sold their concept to another buyer. A tough pill to swallow when your intellectual property is floating around in someone else’s brand. Then there are the customs & trade regulations. Tariffs, import duties, documentation – can add up fast. Have you ever had a shipment delayed at the port waiting for documentation? Best case scenario you are paying storage for nothing. Just last year, one of my clients waited several weeks for a container they purchased due to a minor error in labeling. Time is money folks – and delays, well, both.

Now add in the geopolitical issues. If you have been following the news, you have seen the US-China trade fight, and the supply chain issues that were exposed throughout the pandemic. These items are not just headlines – they absolutely matter to your business bottom line. Tariffs climbing, shipping rates rising, suddenly your supposed “cheap” opportunity from China does not feel quite so cheap. Back in 2019, amidst the increase in trade tensions, I was aware of a retailer that was put through a very tough period, and had to rethink their entire sourcing strategy because of unforeseen duties. It’s a risk that you have to manage. Then there are the ethical considerations. In some cases, there are people that are afraid to source from the China because of labor, or environmental concerns… So, it is definitely something to consider. You don’t want your brand to be associated with something you’re not comfortable with or your customers are not pleased with. I’ve thought about this; these are not easy questions; it’s not just business, but personal. Your values will impact what you are willing to do when it comes to sourcing and this is something to consider.

So, back to ethics, have you thought, consider how much more important transparency is to today’s buyers? Customers are sophisticated now; they dig deep into where your product comes from. If they even sniff out unfair labor practices, they could tarnish your good name. So, while you want to make money in China, you can’t put profits above principles. It’s a balancing act, but one that’s doable. However, I’ve found that being honest about your sourcing will help create transparency and trust, as it exists to some point, even in an imperfect way. It really is a great time to begin making sourcing opportunities in China, particularly openness, means a great deal in a time where people are more skeptical than ever before!

However, the good news is that these hurdles are not dead ends. These things are chasms, that, with some knowledge, can be overcome. To win, you will go down these paths over time and sometimes it takes time to think about them. You will need patience, strategy, and learning. For example, a simple translator will be important if you need communication with suppliers. If you really want to be certain that suppliers are not going to lose you money, consider doing systematic quality control. Paying attention to US trade policy announcements and regulations can be just smart business. I’ve messed up all of these before, and while all of these mistakes challenged my judgement, I learned something from each challenge…and you will too! Remember that it’s the journey that matters and you will miss the path sometimes. Stay with me! I’m going to share some tangible ideas of how you can avoid some hurdles in the way. If sourcing was easy, everyone would do it! Let’s stay focused and talk about what you can source from one of the largest manufacturing producers on the planet! There are plenty of products here available for you to source from!

What can you source? Pretty much anything!

Now that we’ve covered the tougher parts let’s get into the exciting part— what product types you can source from China. To be honest, the selection is mind-blowing. It is like walking through a market where every stall sells something different. It doesn’t matter if you are in e-commerce, retail, or manufacturing; chances are you can find something there. So what are you thinking? Let’s review some of the heavyweights and see where your interests fall.

Start with consumer electronics. This is China’s heavyweight industry. Think smartphones, earbuds, smartwatches—anything techy. Shenzhen is a mecca of gadgets. If you have an idea for the next hot accessory, I guarantee you will find a factory to make it. I know a guy who sourced wireless chargers from Shenzhen and made him some good ROI on Amazon. He initially sourced a small order, tested the market, and now it is the backbone of his business. The tech industry in China isn’t just a bunch of knockoffs anymore. They are a market leader in innovative designs you can put your logo on. Amazing isn’t it?

Next up, apparel and textiles. Whether you want to design the next coolest streetwear, or source bulk uniforms for a local company, suppliers in cities like Hangzhou and Guangzhou will gladly take on custom designs and mass production orders. You can get whatever you want, and I mean whatever you want, from graphic t-shirts to high-end fashion, at prices that will leave you speechless. I’ll tell you a story. I was sourcing a line of hoodies for a client (the whole deal including full customization and embroidery), and the per-unit price was half of what I was quoted from my local shops. Whether you are building a fashion label, or you need promotional gear, there are textile producers all over China that have the capacity and know-how. Whatever you need, you just need to figure out the technical specifications, and we’ll discuss that shortly.

Ah, and don’t forget about home goods and furniture. You need kitchen products that are inexpensive or fancy decor for your e-commerce site? China has your back. The same can be said for toys, knick-knacks, and novelty items. Perfect if you want to tap into children’s products or sales around holidays. Think of all those surprise toys, or “fidget” toys that were all the rage a few years ago. Most came from factories in China. I have seen small businesses source stuffed toys or novelty desk ornaments and find a niche market on Etsy. And industrial stuff! Machinery, tools, even medical supplies (huge exports after 2020, as PPE was in demand). If your business is in the construction trade or health care, the opportunity to have suppliers fill bulk orders or source products with specifications is out there.

Now here’s a thought: in 2023 as we take notice of smart home devices or sustainable products becoming more prevalent and stacked against that, with the number of suppliers in China beginning to adjust to Western demands for sustainable materials or devices with more tech embedded—I’ve seen suppliers even offer biodegradable packaging! Crazy! Okay, maybe it’s not as universal yet, but the process is certainly shifting. So if you have a product in mind and a potential niche, I can almost guarantee there is a factory in China that can manufacturer a version of your product, provided you have already identified the technical specifications (and, just as we’ve established – communication is critical to avoid mistakes).

Oh, and a little sidebar here—if you’re into seasonal goods then you hit the jackpot. For example, Halloween costumes, Christmas lights, Valentine’s Day cheap stuff—they manufacture millions of these products each year! If your timing is right, get ready for some serious money during high shopping periods (like the holidays). I once knew a guy who was sourcing ugly Christmas sweaters by the hundred/thousand, and sold out before December! He planned months in advance, secured a supplier, and made it happen. It’s all timing. Now, think about the seasonal wants and needs of your market, and let’s start sourcing. Next, we’ll touch on how to find the right people to work with inside of China; trust me, it won’t be as difficult as you think!

Locating Dependable Suppliers: Where to Begin?

So you’ve decided you’re going to source from China. Fantastic! What remains is the question everyone asks when first entering the freight jungle: how do I find suppliers that are trustworthy? It is not like you can just book a one-way plane ticket to a factory on the other side of the world and shake hands. Well, sure you could, but let’s be honest – none of us have the time or budget to do that.

So here’s the thing: it does take some work to find reliable partners, but you can definitely make it happen. Let me share some time-tested ways to access trustworthy suppliers. Grab your notebook, you will want to write some of these things down.

Let’s start with online platforms. Online platforms are probably your best option when you first starting out. Alibaba, Made-in-China or Global Sources are basically platforms of suppliers. Alibaba alone has millions of listings for all types of products that run the gamut for technology or textiles. You can browse categories, message suppliers, you can even request quotes from your laptop.

Here’s a tip – don’t just choose a listing based on the first thing you see that has the best price. Look for “Gold Suppliers” or verified accounts on Alibaba, meaning they have been vetted to some extent. I’ve used Alibaba before to find some great partners, but I have also found some turds. Look at the reviews, ask for samples, and chat with the supplier to figure out if they respond timely. Think of it like online dating – don’t swipe right until you get a good feeling from their response! Spend the time to filter the options, and don’t get distracted by the “shiny” deal either.

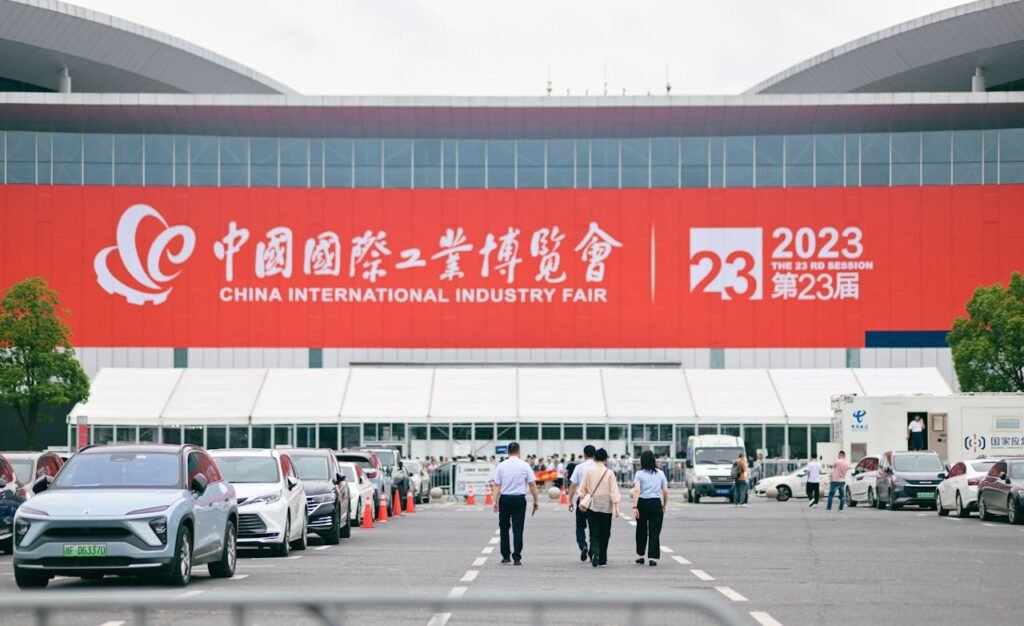

Another great source? Trade shows and exhibitions. If you can afford to make the trip to China( or join an online version), events like the Canton Fair are absolute gems. The Canton Fair is held twice a year in Guangzhou and brings together suppliers from thousands of suppliers across every imaginable industry. You can see products live and in-person, meet factory reps, and negotiate in person. There is also the Yiwu Commodities Fair if you are more concentrated on smaller, wholesale items. I went to Canton Fair once and came back with my notebook stuffed full of contacts. It is tiring – I felt like I was walking constantly through booth after booth – but nothing beats shaking someone’s hand and seeing the products right in front of you. If travel is not an option, many shows now have online portals; go to their websites and check to see if you can virtually attend the event. It is not as good, but you can still get solid leads without the jet lag.

If this is feeling too overwhelming, it would also be worth looking into a sourcing agent or intermediary. These are the people that are figuratively your boots on the ground in China. They speak the language, understand the market, and can vet suppliers for you. Yes, there will likely be a cost – usually a percentage of your order (perhaps 5-10%) – but for a beginner, you can’t afford not to hire them. I worked with agents when I was new to this and they saved me from a couple of bad deals. They will visit factories, negotiate contracts, arrange Logistics headaches, etc. Just make sure to hire someone with a good reputation. You can ask for references or look for reviews online like Upwork or LinkedIn. A good agent can be compared to a trail guide in the wilderness—they help you not to get lost.

Also, don’t overlook the power of referrals and networks. Do you have friends or associates who have procured goods from China? Ask them! Business forums on websites like Reddit or LinkedIn groups can also provide great leads. I have found some of my best suppliers by word of mouth. People generally are enthusiastic about sharing their experiences when they have had good ones—just ask. It’s like deciding on a restaurant, sometimes you can’t google the best spot, trust me on this one. Join a couple of online communities or attend local small business meetups—someone will know someone that knows someone—once, I got an amazing supply lead while drinking coffee at a networking event. You never know when a lead might show up.

My final note is to do due diligence. I know doing a background check isn’t sexy but it is necessary. Use things like Tmall Global to check supplier ratings, or hire a third-party service to research a factory’s credentials. If you can, visit the factory or have someone else do it. Being able to see their facility, meet the people, and see their process can save you considerable headaches later. I learned this the hard way when I found out my supplier was not even the owner of their factory—they were outsourcing everything. Lesson learned. Verify their business license, ask for references from clients, and research reviews online. A little investigative work now is better than regretting later.

Finding suppliers is only the first step. You need to establish a relationship of trust and strong communication going forth. Be up front with your needs, don’t make decisions too hastily, and take the time to verify. Building a working relationship with suppliers is akin to establishing a friendship—requires some effort but ultimately is worth it. I have many times had suppliers go above and beyond once they saw I was serious, such as rushing a small order for free. This trust does not happen overnight—it takes time. Next up, let’s break down the actual processes used in order to successfully source products. Are you ready to get in to detailed sourcing? Let’s plot out how we can get those supplier contacts turned into actual products.

Now that you’re aware of some places to find suppliers, let’s get into the nitty gritty—how to source from China successfully without losing your backside. I’m going to try to break this down step by step almost as if I’m giving you a recipe. Incorporate those things that work for you, change it up when you need to, and you’ll be a short step away from getting products made and shipped. It’s not brain surgery but it does require focus. I’ve bungled through it myself (with a lot of learning in the way of oops moments) and I’m here to save you some grief. So let’s roll up our sleeves and get into it.

Step 1 – Define what you want. This seems easy, right? You’d be surprised how many people skip this and end up with a little lesson in chaos. Write your product specs down – size, material, color, packaging and so on. If I was sourcing a backpack, for example, I would write down things like straps, zippers, fabric type, the amount of compartments, etc. I would be as specific as possible. When in doubt, assume you need to be specific. If you forward vague instructions, your results are going to be vague. I once ordered a “batch” of mugs and forgot to mention handle type, and unfortunately, I ended up with mugs I couldn’t sell. It also helps, when it is appropriate, to draw a picture of your intended product so your suppliers can see what you want. This is also helpful if language is a problem, since your suppliers can see your perspective. You’re basically creating a blueprint for suppliers, and you can relate to how difficult it is to source with no blueprint. Don’t forget the quantity you want either… get to know whether you want 100 or 10,000 units before you start talking. Getting clear on this now may alleviate some confusion later.

Next, once you’ve defined your product, you can start to research suppliers and individuals they work with—this may not be the end of it. Using the strategies we just discussed—Alibaba, trade shows, agents—explore a few potential partners. Don’t settle on one immediately, but get quotes from at least three, preferably five different suppliers. Look for MOQs (minimum order quantity), lead time, and pricing. Some suppliers have really high MOQs, like 1,000 units, which is likely not an option (if you are testing a product) and other suppliers may have really low MOQ, like 100 units, but for higher per piece costs. Compare apples to apples. I usually create a quick spreadsheet to keep track of it all—it helps me stay organized. Note communications as well, a supplier who communicates quickly and concisely is worth their weight in gold! (I’ve dealt with slow to respond suppliers before, and it almost cost me a launch deadline) Once you’ve narrowed your list down to your tops, dig deeper with questions about their process and capabilities.

Step three: request samples. Don’t—you hear me?—don’t order from them without getting a sample first. Most suppliers will send you one to examine for a nominal fee, and sometimes they are free. Examine it. Try it out. If it breaks, breaks, just try it out. Either way, make sure it meets your specifications, and expectations for quality, etc. I have received samples that looked perfect, and then the final batch was junk! So, not only order it with the first supplier, next order another sample from a different supplier, and then you can compare. Is that process time consuming? Sure it is. Worth it? You bet. If it is a gadget, plug it in and put it through its paces. If it is some clothes, wash it or wear it, and check the seams. I had totes made as a sample. I liked the look of the first one supplier, but the stitching came apart. I missed a bullet with the second option. Samples are your friend, and you want to get samples, even if you want to rush it.

Once you select a supplier, then it’s negotiation time. You will now negotiate prices, minimum order quantities, shipping time, and payment terms. Negotiation is second nature in China. Don’t be shy to negotiate. Present your price low, but also be realistic. You don’t want to offend your supplier by low-balling them. Also, be sure to ask for discounts for a bigger or faster order. I have negotiated costs down by 10% and 15% simply by literally just asking. Don’t be overbearing but be firm; you want to be friendly. When negotiating with vendors, having rapport is key. Also negotiate payment terms; the most common is 30% upfront, 70% on delivery; this can also be paid bank to bank or PayPal. Use secured methods & avoid Western Union if you can. I had a supplier looking to get full payment up front—a red flag. Use staged payments so you are protected. Also, agree on timelines; confirm with your supplier the timeline for production and shipping and get a written copy of the timelines. Just like the beginning of a larger project, use this opportunity to set ground rules; everyone must get on the same page.

So we have discussed the initial steps to sourcing from china. You have an idea of your product, shortlisted suppliers, received samples, and negotiated terms. Here we go again, let’s dive back into our road map and finish out the final step or steps—it’s all the little things that pull the pieces together, so don’t rush through them. I’ve learned by making mistakes that if you skip one step, it can throw everything out of whack. I’m going to keep this simple and straightforward!

Step 5, quality inspections. You should do checks before you start production, during production and before you ship. You can hire third party services such as Bureau Veritas or AsiaInspection to fly someone to the factory, look at your goods, then provide you with a report of how they measured up to your specifications. If you are in China, you can do this yourself (hopefully, you established some relationships). You should do the pre-production inspection to confirm that the materials you paid for are right, I wouldn’t want to get cheap plastic after paying for assembly in metal. In-process inspections help you find problems mid-production run (for example, if a machine has a problem, it can ruin thousands of units). And the pre-shipment inspection will confirm that the final batch of product is the same as the sample that you checked before starting production. I once skipped an inspection for a few bucks and then I had to deal with half of my entire shipment being off-spec—see how this can go wrong? Do not make my mistake, you need to spend the $200-500 for the inspection if required. It is cheaper than a product recall, or angry customers.

Now we get to wrap-up with a contract and shipping. Make sure your contracts are in writing—an email string isn’t enough. Include required specifications, delivery schedule, payment schedule and penalties for late deliverables! A basic contract from a legal template site like Rocket Lawyer is great, but if you are using a big enough of an order, I would suggest to use your lawyer. Next you will need to sort out shipping. Is the supplier going to take care of the shipping (FOB (freight on board) or CIF (cost, insurance, freight)), or are you going to deal with FedEx or a freight forwarder? I’ll cover shipping in more detail in another section, but it is important to put this into place early. I have had the shipping delayed simply because I did not clarify who was doing what, so please make sure to dot every “i” and cross every “t” here.

Wow, that was the entire process! It’s hard work, but if you follow the steps properly, then each part helps the next. If you create a problem in one part, the falling dominoes begin to move quickly! Take your time, check things twice and don’t jump ahead. I have jumped takes before, and I can say it cost me along with headache and lost money. If it makes it to market, it is easier to live with a slow and steady pace than as a rush job, with mistakes and missed opportunities. Okay, now I want to talk money! How much does all of this truly costs? Here comes a spoiler alert…we’re not only talking about the product price tag. Let’s break the costs so you aren’t catching a surprise of costly errors.

I want to talk about dollars—Yuan in your case. Sourcing from China sounds inexpensive and it can be, but the price of your product is just the beginning. There are layers of costs that can sneak up on you without your attention. I have paid the price before, budgeting tightly and suddenly slamming into unexpected fees that chipped away at my margins. So let me clarify some of the costs you’re going to hit. Get a calculator or a spreadsheet, you’re going to want to do some number crunching with me along the way. Trust me, by planning in advance, you can avoid a lot of extra expense later.

First, the product cost. Suppliers quote per unit, but usually tied into MOQs (Minimum Order Quantities). A gadget could be $5 for 1,000 units but $8 for 500 units. You want the lower price, a lower price is always better upfront. However, you need to also have a realistic gauge if you are going to sell that much inventory. Samples alone—$10–50 each and sometimes more. Negotiate hard, but don’t expect the world. You usually do get what you pay for, and if you negotiate for rock bottom prices, you’re more than likely getting a rock bottom quality. I have always built my budget with about a 10% buffer when thinking prices, and price increase, and add-ons (like custom packaging). For example, I once sourced a set of kitchen tools and mid-way through the order, they informed us they would add costs to our order for branded boxes. Annoying, but common. Ask about set up fees for customisation, as many of them never disclose these fees unless you specifically enquire about it.

Then, shipping and logistics. If you’re not careful, this can be a budget killer too. Air freight is super fast, but also expensive–think $5-10 per kilo for a small batch. Air freight works best for urgent or lower cost items, such as electronics, where an air shipment can take days. Ocean freight is cheapest, where a 20-ft container might cost you between $1,000-$3000, but it takes weeks to ship. To give you an idea of timing, it takes at least 30 to 40 days by shipping from Shanghai to Los Angeles via Ocean freight. Rail is a less popular, growing alternative with the Belt and Road routes that are now available for imports from China, and it is still generally faster than shipping. It is also limited to very particular regions however. The cost will vary depending on distance to destination, weight, and urgency of shipment. Don’t forget to consider the cost of port fees, and also shipping from the port to your inland destination. I had a shipment worth $2,000 which I thought would have an $800 cost, but I did not factor in the cost for the last mile shipping (from the port to my warehouse location). Know your Incoterms. If you have an FOB agreement, you will be responsible for paying costs from the port. With transport under CIF, shipping is included partway. Don’t let yourself be lured into costing or being liable for something you did not intend to include!

Import duties and tariffs? Very scary! Depending on where you are, and what you are importing (look up HS codes for classification!), you could pay anywhere from between 5% to 25% (of your product value) in import duties. Given the current US-China trade tensions, some of the goods you import may have added tariffs to their cost. Since 2018, there have also been tariffs increased from 10% to 25% on some goods that could affect your cost with the current US-China trade tension. Don’t forget to calculate your costs for sales tax and/or VAT on the whole purchase too! You can typically find these rates on your own customs website (cbp.gov for the US), or you can hire a customs broker to navigate this area for you. I once thought I could get away with underestimating $1,500 worth of tariffs on a shipment of goods, and ended up doubling that forecast. I wound up losing 50% of all of my profits on that order of goods. If you plan ahead for these costs, do not discount it as negligible! Websites like SimplyDuty.com can help you make estimates, but it’s best to verify with official government websites. Tariffs are not a suggestion; they have to be planned for.

Currency changes and fees to make payments can also eat into your profits. If you are paying a Chinese supplier in USD,

Quality Control: Don’t Skimp On It!

If there’s one thing I’ve learned the hard way, it’s this: quality control is never negotiable, and I don’t care how cheap your production is. You can get products made for a song, but if they arrive in a terrible state, you’re dead in the water. Nobody gives a rats’ ass where it was made; they just care that it works, or lasts. I’ve had shipments arrive that were so defective that they ruined my reputation with buyers. Don’t let one bad shipment ruin months of your hard work. So let’s cover the steps of ensuring you get what you expect. I’ll say it again: it’s worth it, and that’s coming from someone who gets it can feel like a pain in the posterior.

Why is quality such a big deal? Because not all suppliers are created equal. Some suppliers are interested in speed, or cost, rather than durability. Others will change materials without telling you—e.g., you think you’re getting metal, but you get cheap plastic instead. A buddy of mine ordered fitness gear, and the weights were far from specs. All he did was refund angry customers, and it cost him. That’s the kind of trouble you don’t need. Quality problems equal wasted time, money, and trust. If your product fails, your brand suffers. Online reviews don’t lie, and bad reviews spread like wildfire. I know small business owners who’ve struggled to recover from a bad shipment. Don’t let it happen to you.

So how do you do it? Start with standards. Your product specifications — those specifics we spoke about earlier — are not just for ordering; they’re your base line: you should give them to the supplier, in writing, possibly with some pictures or diagrams. And, set tolerances (like 1mm margin of error on sizing). I have used specification sheets with numbered callouts to avoid mix-ups: it’s like you are giving a teacher a rubric for grading. In the long run, clarity at the front end saves you a lot of grief in the back end. Tell the supplier what “good” looks like and get them to confirm in writing. I made the mistake of assuming a supplier understood “waterproof” for a product; it turns out their definition of waterproof was water ” resistant.” A huge difference, a huge problem. Just say it.

Then, inspect; every stage. Pre-production inspection helps you confirm the raw materials match your order—imagine if you had the wrong fabric for a clothing line. During production inspections identify issues mid-run; if it’s a problem with a machine losing alignment, you will know about it before the factory makes you 10,000 incorrect units. Pre-shipment inspections confirm the final batch, just before it leaves the factory. With supply chain inspection options, there are various third-party services like SGS and QIMA, that send inspectors to the factory for $200-$500 for each visit and will provide you with a detailed report with photos. I have inspected dozens of products over the years with third-party inspectors, and there are flaws I could have easily missed, like the stitching on bags, which I would not think would be a problem. If you’re near China, go to the factory—the best way to do it is to eyeball it. A friend of mine went to the factory, and while he was there, he identified some equipment was out of date; he was able to switch suppliers right there and then. So worth your time.

What if you can’t afford inspections? At least ask for progress updates on a regular basis, this would include photos, videos, and batch samples. Build it into your contract. And here is a little trick: when placing an order, order an extra batch, like 5% more, to the account for the defective units you usually get. I had saved myself all this hassle like this when a couple units didn’t pass. But nothing beats a proper inspection. Don’t gamble, “ it will be fine.” I did that once, and I had a batch of toys, and half of them had loose pieces; I couldn’t sell them. I had to scrap the order and lost $800. A $300 inspection would have prevented it. It is basic math; if you cheap out on quality control, it can become more expensive in the end.

Also, foster long-term relationships with suppliers. Often, suppliers will not cut corners if they know you are an existing customer. In fact, I have had a supplier go over and above once the trust was established, like the supplier fixed an error on my batch for free. Communicating also helps; in the case where something is not right, express your point honestly, but calmly. I have provided detailed feedback to suppliers, containing pictures of problems, and they fix things extremely quickly if they are a good supplier. Supplier quality is not a one and done; it is a way of life. You will need to stay on top of assessing quality with every new order, regardless of size. Next up, communication, and how you communicate with suppliers will likely make or break everything. I have found that it is all well and good to understand the spoken and written language; however, in this context, you are trying to establish a connection of sorts across a number of cultural differences.

Cultural and Communication Tips: Mind the Gap

Here’s where things can get a little tricky, but again, one of the most critical areas: cultural differences and communication when dealing with sourcing in China. You are not only working across borders, but soon you will find out this is a completely different way of conducting business. I have messed this up myself—misreading signals or coming off too assertively—and could see the difference in time and confusion. I’ll give you some perspective on this so you can avoid the same pitfalls I have. It’s less about language and more about mindset. If you get this right, you can smooth out lots of bumps down the road.

First, get a feel for the business culture in China. Sometimes the relationships (also known as “guanxi”) are more important than the contracts. It’s about trust and respect. In the west, we are pretty much trained to get right to the point, but for Chinese suppliers, it is usually preferable to spend some time on small talk and build the relationship. Get to know them a little. Ask about their family, talk about the weather or a holiday (Chinese New Year, for example) before talking about business details. I’ve found a simple “How’s your day?” can loosen things up a little and lead on a friendly note. Don’t press too hard for a “no”, Chinese people can be very indirect in their answers to avoid losing face. If they seem evasive or vague in their answers, take that as hesitation. It’s like a subtle dance – learn the steps. I’ve pushed too hard for answers when I needed to slow my roll, or confidence takes over and I was oblivious to the reality that I needed to allow for them to politely say “no” indirectly. Patience is the name of the game.

The most obvious obstacle is language. Presuming you don’t speak Mandarin, you should expect some gaps. Emails can definitely get lost in translation as literal wording can turn around meanings in the way one needs to learn to discern subtleties.in language. I once wrote “urgent” and they interpreted that to mean “angry.” Use straightforward wording, avoid slang and idioms; they won’t even compute something like, “beat around the bush.” Google Translate is great, but for the larger deals, you may want to get a translator or hire a sourcing agent who speaks the language. I have also used We Chat (very common in China) for short exchanges—voice messages seem to clear up a lot of the confusion of text.

It’s also good to always verify their responses by re-phrasing what they said. If they say we could do 500 units by next month, you would reply with, “Just to verify, are we talking about 500 units by Nov 15?” I have been able to avoid problems this way. Sure, it is a pain-in-the-butt, but getting a shipment of the wrong product is a bigger pain-in-the-butt.

Time zones complicate everything. They are 12–15 hrs ahead in China. If you send them an e-mail at 9 AM your time, you shouldn’t expect a response until that day is over (after midnight). Make sure you are planning for this—don’t think that the last-minute contacts (whatever you think the last minute is) are going to get a response right away. Even if that was your first contact, I have missed program deadlines when I thought their response was going to come during the day, or same-day. Be realistic about timelines and always include buffer days. If you need something by Friday, get your order request in on the previous Friday. You need patience! I’ve started scheduling calls—5 AM my time to get the advantage of talking real time. It is a bummer sometimes, but in a live conversation a lot of confusion can be quickly cleared up. There are several apps you can use to help you with the time difference, like World Time Buddy.

Lastly, negotiation style in China is a whole different animal. Negotiation is expected in China; don’t take an aggressive tone. You should begin your negotiation with what you think is a fair price, not a low-ball price, and then build upon from there. They may respond to your questions with protracted silence or ambiguous words – don’t take it personally, this is purely strategic. I have learned to smile, be nice, and calmly reiterate my needs. If you can meet in person it’s best; video calls via Zoom are a second option. By showing your human side you’ll build connections. I once was involved in negotiations via video call and made a joke about the weather – it broke the ice and we were able to establish terms very quickly. Keep in mind, its typically not just business; its a personal connection as well. Check your lens and you’ll find the suppliers have a much higher chance of meeting you half way.

Here is a quick aside because have you ever noticed how there is a timing aspect to cultural stuff? When you coincide your little gift such as sending a box of mooncakes during the Mid-Autumn Festival you can perhaps earn yourself some brown points. It certainly is not a bribe; it is goodwill. Take my it I have done this before and the response has been warmer. It’s true what they say about little gestures; it is all about showing respect. It’s like remembering someone’s birthday, a little effort can go a long way. Anyway, back to the legal side, because while it is good to be friends, you still need to cross your t’s and dot your i’s, Trust is good, but covering yourself is better! Let’s make sure you are covered.

Legal & Contracting Essentials: Cover Yourself

Let’s get serious for a moment. When you are sourcing from China, you are putting your business in another legal realm, and if you do not have written contracts, you are exposed. I have seen businesses lose thousands of dollars because of a handshake, not a signed document. It’s not about questioning the integrity of the supplier; it’s about understanding the legal side and having protections in place. I want to take you through the legal essentials so you know you are covered. It isn’t as scary as it sounds and a bit of advance work could save yourself a lot of trouble later on.

First and foremost-always, I mean always, be sure to have a physical contract instead of emails, messaging or texts, which won’t hold if things go wrong. The contract should identify all expectations: visuals or specs for the product, pricing, timelines for delivery, payment terms, and what happens if something is late or defective. Simple language but very specific. I have used a lot of templates from sites like LegalZoom and modified them as I needed. Also make sure you include a couple of clauses about intellectual property. If your design is unique, claim it, and say it cannot be shared or copied. IP theft is not rampant, but it certainly exists. I’ve known of small brands who found their own designs on other markets because they hadn’t dotted their I’s and crossed their T’s; better to err on the side of caution. The value of even a simple clause stating, “This design is confidential and exclusive to [Your Company]” is critical to your defence.

Next, be clear on some key terms. For instance, your payment schedule like 30% deposit and 70% upon delivery are fully documented. Be specific about who is responsible if shipping goes wrong or if customs holds the order, don’t be vague. Set out clearly what happens if deadlines are missed; for example, penalty discount rates which are penalized each week after the deadline, such as 5%. I have gotten suppliers to agree to minimum penalty rates from me, and documented it so that they are accountable themselves. Also include how disputes get resolved. Arbitration in a neutral location like Singapore is common, as I would opt for Chinese courts which may have a tendency to favour locals in the dispute-resolution process. I am not suggesting this is earth shattering hard reading, but it may save you for or having to spend longer periods dealing with disputes. If you are spending significant amounts of money ask someone like a lawyer with expertise in international trade to review the agreement. An expert usually costs a few hundred dollars, but can save you $10,000 if you should unexpectedly walk into a crisis after pre-payment. If I recall right, I think I spent $500 on legal advice when I was packaging a $20,000 order; but I would spend a million dollars to have leverage if I was in a bind because of an issue and it is a helpful outcome.

You might want to get yourself familiar with a little Chinese business law too. Contracts are enforceable, but local laws are often favoured in disputes. Like I mentioned earlier, Chinese courts might not act as you might expect. Again I would build in some safeguards to your agreements. I have reached out to trade experts which the chambers of commerce have, and they often offer help to businesses for free or a minimal cost. Finally, make sure you keep records of everything. All emails, invoices, photos of your samples etc. Record-keeping is a life saver if shit hits the fan. I had a supplier reply to an email that they “never agreed” to a term in our agreement, which I screen-shotted and opened up the saved email chain with our agreement in it, and that specific supplier had no other choice but to backtrack. Have your proof, and proof wins debates. Keep digital backups in the cloud, and hard copies in print form; as you do not know when your records will be needed.

But don’t panic. Ultimately most suppliers want to ensure repeat business; they are not intentionally going to tarnish their reputation over a minor issue. Just be very detailed and thorough. To demonstrate this, I have had contracts literally rescue me when suppliers tried to increase their prices after we had just agreed to a bill of lading. I simply pointed out the signed contract and they agreed to honour the original quotation. Having a contract is like a safety net, you just hope you never have to use it. Now, let’s pivot to shipping, as getting your goods across the ocean is another beast altogether. Even with a solid contract, logistics can trip you up if you’re not prepared.

Logistics and Shipping: Bringing It Home

You’ve already sourced your product, sorted out the contract, and are ready to go. Now you have to figure out how to get it from a factory in China to your doorstep. Shipping and logistics can be the deciding factor behind your timeline—and your budget. I once had a shipment delayed for weeks, resulting in lost sales, because I didn’t do the proper planning. Let me walk you through the options and pitfalls, so that you get your goods delivered without incident. This is where it gets real, and a little knowledge goes a long way.

Let’s start with shipping methods. There are a few major methods, each with their pros and cons. Air freight is the fastest, measured in days not weeks, but is expensive—$5-$10 per kilo. It’s good for small, time-sensitive, or high-value items like electronics. If you have a hot product launching and need 200 units delivered ASAP, air freight is your best bet. Sea freight is significantly cheaper, ranging from $1,000-$3,000 for a 20-foot container, but will take anywhere from 20-40 days, depending on ports of origin and destination ( for instance, Shanghai to LA). Sea freight is good for bulk or heavy items like furniture. Rail, for example China-Europe services or via the US intermodal, falls somewhere between Freight and Air. It will be faster than shipping by sea freight and has a lower price than air freight, but there are limited origin and destination options. Finally, there are express courier services (DHL, FedEx, etc.) that you can use for tiny batches of product; while express services are, of course, quick, they are also very expensive, ranging from $20-$50 per kilo of product shipped. I have used sea freight to ship furniture, and air-freight to ship last-minute technology; in choosing a method, suitability needs to be valued against cost. It’s all a matter of weighing your timing against your budget; sometimes, getting there ASAP is not worth the additional cost.

Then there are the incoterms, which are the terms of trade that define who pays for what. FOB (Free on Board) means that the supplier is responsible for the costs to get it to the port, you will take care of shipping from that point onwards. CIF (Cost, Insurance, Freight) means they will ship it to your port; however, you are responsible for customs and everything onward. DDP (Delivered Duty Paid) includes everything to your door, this option is usually the most expensive and the easiest. I like FOB because it gives me control over who ships it; even if everyone will just use their standard carrier. You need to confirm the Incoterms with your supplier – this is important because things can go wrong, and they can go horribly wrong! I once made an assumption and thought a CIF option covered everything and then was hit with unexpected fees when I arrived at the port. Always read the entire terms of shipping or take a few minutes and ask a freight forwarder to explain it to you. I know it is just jargon, but is important jargon. If the contract states that you are responsible for charges from Shanghai or just your local port, it could greatly impact your budget.

One thing I can tell you about freight forwarders, is they are your friends. Freight forwarders are middlemen who handle all aspects of shipping, including completing the paperwork and clearing customs. Companies like Flexport or UPS Supply Chain Solutions act as shipping agents for you. They can book vessels, track shipments, and navigate all the red tape that comes with shipping internationally. Depending on the shipment, the cost of freight forwarders are $500 – $2000, but I promise, you will save countless hours of time. I have used freight forwarders for every major order I have done, and they have saved me time, caught errors that I would have missed (wrong labels on containers). Pick a freight forwarder that has experience with shipping from China, and ask your suppliers who they recommend! A great freight forwarder is like a travel agent for your goods – they know the shortcuts. They have saved me days and dollars in shipping when they would tell me which routes to take and avoid during peak seasons.

We have now covered the differences of shipping methods, the relevancy of Incoterms, the job of the freight forwarder and what they accomplish for you in order to get your goods from China.

Let’s wrap up this section by looking at the last pieces of the logistics puzzle—customs clearance, tracking and dealing with disruption. I have endured more than my fair share of shipping disasters and these steps can make the difference between a delivery success or a total wretchedness. Let’s just hope that your goods make it home without too much hassle.

Customs clearance can be a nightmare! You will need an entire bundle of paperwork—a commercial invoice, a packing list, a bill of lading and sometimes certificate(s) (for example safety standards). Mess any of these steps up and your shipment may be held in limbo at the port. You will be liable for duties, taxes, and port fees– budget for 10–30% of product value depending on your country and type of item! In complicated situations use a customs broker ($100–300 per entry) so you don’t have to jump through all the hoops. I’ve had shipments held simply for missing paperwork and it cost me over $800 in storage fees after a week! Look up your country’s custom site (for example, in the US CBP.gov) to understand what is required and prevailed. Don’t guess; this is important. Assume nothing! Keep copies of everything (digital & physical) as we all know things can get “lost” in their systems. It is annoying, but if you prepare it helps with moving things along!

It should go without saying, but tracking your shipments is the same! Most freight forwarders will have portals or apps you can use to see progress. Knowing whether your container is stuck in Singapore or if it is delayed off the coast of California allows you to update your plans. I have used the tracking system to advise customers of potential delays before they even reached out to me– saved me my reputation. Technologies like ShipTrack or even simple tracking through the carrier’s website will do (e.g. Maersk, FedEx). Make sure you check at least daily while in transit as things can change rapidly. I once neglected to check tracking once for a week and was horrified to see my shipment had been rerouted due to a storm! I lost 10 days due to being distracted! You should always keep abreast of the status of your shipment, even if it feels excessive. A quick review in the morning can help you catch issues quickly.

Disruption will happen on a global scale (COVID-19, port congestion in 2023), so if anything, assume the worse even when you think things will land on time. Add weeks to your projections! I once waited 60 days for a shipment that was supposed to take 30 days due to congestion in the Suez Canal (just a few years back). Flexibility is important. Monitor freight news on caster type sites like FreightWaves for warnings of impending bottlenecks. Backup plans are important—split orders across carriers whenever you can, or have extra inventory on hand and use it if you have to. Disruptions are not personal; they are just part of reality. As we both know, plan for the worst, but hope for the best. Now that we have looked at freight shipping, let’s look at ethics, because how your product was made is just as important as how you had it shipped to you.

Ethical and Sustainable Sourcing: Do It Right

Is sourcing from China only about economics? Yes and no. There are principles too. Today’s consumers want to know where their products come from. Whether it’s the labor conditions, or environmental impact, they want to know. I’ve wrestled with this myself – how can I justify a good price if the manufacturer practices are questionable? Let’s chat about ethical sourcing and how to balance business and doing the right thing. It’s a tough line to walk, no doubt, but well worth the journey. Your brand’s reputation is built on more than price and quality; it’s also built on values.

Labor conditions in China have been scrutinized over the years and most of the time, somewhat warranted. We have seen stories and even photo series on low wages or workers maybe working too many hours in factory conditions. Not every supplier, manufacturer, or factory, is guilty of this, but you have to take an initiative to check. Request factory audit documentation or evidence that a labor standard was imposed (like a SA8000 certification), so you can have some verification that the labor standards were measured. For a few hundred dollars per visit, you can have a third party inspection assess and verify if your workers are being treated fairly. I have switched suppliers because the condition of the workers were poor. It was more expensive, but frankly, my sleep is worth it! Also, talk to your supplier and ask what policies they have in relation to wages and overtime. Most manufacturers value their place in the global supply chain and will do whatever it takes to meet western expectations, especially with global scrutiny towards worker conditions increasing. Traffic to your brand is based on trust; one exposure from an external even from an unknown source can drastically impact your sales; I have seen social media dismantle small business sales over news stories with labour scandals. Don’t let it happen to you; it’s much better to do your due diligence.

Environmental sustainability is the second biggest picture of concern. Manufacturing can be a dirty process from air pollution, landfill waste, to energy waste. While China is getting better with stricter regulations and standards and new green technology, not all manufacturing plants are on board. Look for ISO 14001 certification (i.e. environmental management) and verify if they have any recycling programs. I have sourced from factories that are powered by solar energy; it may have been more expensive, but you could mark it accordingly.

Consumers love “eco-labels” (if it’s legit) and what’s better is seeing those little changes, like biodegradable packing materials, added up. One time, I marketed one of our products as “sustainably sourced” and I had the proof of the green packing and the sales increased 10% for customers willing to buy green. It’s not perfect, and I’m certainly not changing the world, but it’s a start, and I feel good knowing I’m not contributing the mess.

What about ethics? You can build it into a contract, specify no child labor or mandatory overtime requirements, and demand that companies apply the rules laid out in the various international standards. You can even schedule a tour of the factory to see if you can watch first-hand what the conditions are. I have used a video call to tour facilities that I could not get to, and though I could not see everything, I could see a cramped operational area and I walked away. You can’t be transparent and simply explain to your customers where you source your materials and what your attempts are in being responsible. You can build trust with customers by being honest about what you are doing to improve. I have experiences buyers thanking me for being honest about my attempts to be responsible, not just claiming to be perfect. Honesty counts.

Just a side note, have you noticed how much younger consumers value ethics? Gen Z would bolt at the first sign of unfair or unethical practices tied to the brand. Sourcing responsibly is not just ethical, it’s just smart marketing for 2023, so consider that when choosing your partners. Now, let’s consider how global events impact your future sourcing, because it’s a crazy world out there these days and no planning is immune from external chaos.

How Global Events Impact Your Sourcing: Be Flexible

Sourcing from China does not happen in a vacuum. Global events – pandemics, trade wars, supply chain crisis – can jack your plans. I have had shipments delayed or costs increase from the source of something one hundred percent beyond my control. Let’s explore how the larger issues influence your business and how to take a hit on your chin. It’s all about flexibility, because the unexpected is … well … expected.

COVID-19 blew supply chains up. In 2020, factories closed, ports became clogged and shipping rates peaked at 4 times the normal. In 2023, we are still feeling the residual effects. Shortages in labor or lockdowns in China can delay production runs. Before Christmas a few years ago, I waited three months for a shipment during the peak of pandemic chaos; needless to say, my clients were unhappy, and I lost revenue. I took away the lessons that we need extra days to build in buffer time, and added 4–6 weeks to my timeline—not including holidays or vacation time—thinking about the timeline after everything seemed to be pretty stable. It is just as good practice to diversify my sourcing—don’t put all my eggs in one basket. And, I try to keep cash extra; I allocated some cash reserves because I will guarantee freight raises that will go up by at least by 50% auto, in some events doubling. I have been budgeting an extra 20% for an order just in case a crisis happens mid stream; also realize the pandemic is still something to consider inducing unpredictable small infectious outbreaks still has a stronghold. I just want to give the importance staying prepared.

The US-China trade wars introduced tariffs on US imports, and have added from 10–25% on many categories since 2018, think about the increased cost of a $10,000 shipment to $12,500 shipment because of duties. Tariff Lists on USTR.gov, if you are stationed in the US, let you investigate further for product listings, realizing that you know there are some exemption on product categories but most probably not. Personally, I have rerouted small orders through other countries to avoid duties, but it is rather complicated and might not be legal—so if doing this, please consult a customs broker. Lastly, keep an eye on the news—things can escalate quickly and erratically. Maybe budget more for duties, think about sourcing elsewhere on some items such maybe Vietnam for higher tariff items. I’ve chosen to get some electronic parts out of China and some from Thailand to manage risk, it’s been a hassle and now I’m having to deal with constant policy changes as policy changes with politics so don’t find yourself a panic on a headline,

China is becoming more expensive, and while some have started “near-shoring” – which involves securing supplies as close as possible to home, – I have heard of others looking at countries such as India as alternatives. Even India is not as cheap as it was 10 years ago, and others countries pricing is now competitive as well. I have spent time on India for textiles but for almost all purposes for the way I do business, China’s infrastructure, scale, and speed work way better. Watch for trends; don’t overcommit to a source of supply forever. Dealing globally moves fast, and while today’s opportunity looks great, it may not look as great tomorrow. I started researching alternate countries, as a back up and to know what markets exist, to regenerate opportunities every six months. I can see a time in the future where I would source in a hybrid approach of half the parts out of China and half out of another country which would give me a level of balance, which then allows for flexibility. Flexibility is important because a major event can change years of planning, similar to the tech world there is the need to find balance to support self-sufficiency. Next, we’ll see how technology can improve these experiences and help keep you on the leading edge.

There are many tech and digital tools that can be your partner when sourcing overseas, especially China. From finding suppliers, tracking shipment of goods, there are many applications that reduce stress and save time. I rely on applications and web tools to eliminate some of the stress of processes that were once weeks long processes. Let me highlight some of the tools you can investigate to help you plan. You have a full plate right now so let technology do the heavy lifting for you. If you do this right, you will get the freedom of a colleague; joining your team, who never sleeps.

You’ll have to think of e-commerce platforms like Alibaba as an ecosystem, not like directory. Use chat to connect with suppliers directly, trade assurance (escrow protection for your payments), and supplier rating system to vet suppliers and partners. I often filtered suppliers by “verified” rating so I do not get scammed. I caught one scam supplier that way. Many of these platforms have built-in MAP (Translation) features to have basic communication, just don’t rely on it for a contract. The Alibaba app now allows you to take a photo of your product idea and search for similar products—very handy way to get some quick research on numbers and types of similar designs. I have connected with some other potential niche suppliers through similar searches I would never have found while mining through the scroll of listings. Spend an hour using – it will soon level, and you will find some gems.

Then, there is the issue of Communication. The primary communication tool in China is a chat application called WeChat. It’s like WhatsApp only for business. You can share files, voice notes, and video call your suppliers. I have also closed contracts using WeChat very quickly; suppliers check WeChat much quicker than email. Voice messaging is an easy way to bypass typos with the language barrier. During production, I have sent an update through WeChat, and received an update back within a day with photos. It’s personal, builds trust, and removes the waiting period. Download it, connect with your suppliers, and keep your chats professional and friendly. It makes for a world of difference when you are on a tight deadline.

If you’ve been following me, it’s probably clear to see that I am an advocate of the value or efficiencies that technology has available when sourcing in China, and before we move on, I want to identify a few tech tools that can help and keep you competitive! I’m a fan because I was able to save hours of monotonous manual work. And, I can assure you, when you are trying to source products that have several parts to them, you don’t know how valuable technology can be to make it easy for you.

Supply chain software will always track your orders, and as you can imagine it’s lifecycle. Software like ShipBob or Freightos will tell you where the shipment is located, provide you cost estimates, and tell you if there is going to be a delay before it gets complicated. A good example is Freightos; I got shipping quotes on shipments from my carriers in less than a matter of minutes. Just the other day, I even had a much more affordable route come up as an option on Freightos than what I was intending to use and ended up saving an additional $500 dollars on my order! A lot of the platforms will even integrate with customs and give you heads up on potential delays coming through ports; I had products delayed one time because I didn’t account for this. It helped me save about a week in delivering my products due to congestion that I’ve received a warning about from Freightos. Most of these platforms have a free tier or trial period, so take the time to give a few a try. If you expect to order more than one shipment, it is no longer just a nice to have, it is now must have; it helped me liberate my mind to deal with several suppliers and timelines.

Data analytics – such as Alibaba or Global Sources – can help read supplier trends, like pricing, history, and volume. Some of these platforms even have basic artificial intelligence algorithms built in that suggest reliable partners from previous orders or positive comments. I was able to use Alibaba’s data analytics in about one hour to search for suppliers that consistently received a 5-star overall rating in my niche, and reduced the list of suppliers from 50 to 5! Additionally, there are also standalone tools such as Jungle Scout who are also supportive of the e-commerce crowd – helps gauge market demand before committing to sourcing. One of the biggest things technology allows you the opportunity to do is create strategy instead of guessing. There are actually even AI Chatbots on some websites answering quick questions – very helpful at 2am when you are thinking about your MOQs, I don’t want to make this sound like a blanket recommendation because it still needs to be used correctly. Still, it is nice to be able to get a few of those questions answered! Technology is not the magic fix to your sourcing anxieties, but it can at least take you a few steps ahead in using it the right way. Now let’s begin with the main part of the conversation—real stories—the successes and failures of others so you do not make the same mistakes.

When you are sourcing from abroad, you need to be looking out for the others who have had successes or failures. I have compiled a few real life examples of sourcing from China that were both inspirational and cautionary. I must say, none of these stories are mine (well, one story is my story), they are from folks I have met over the years as we all travel the same road. Let’s look at our actual successes/losses and what you can learn through their experiences. So make yourself a coffee, because these are real eye openers that carry lessons that will spare you a lot of headache. Real life experiences can clarify theories like nothing else.

Let’s begin with a success story. Sarah, an e-commerce seller sourced pet toys from a supplier in Shenzhen through Alibaba. She made it a small test order as she started with 200 units spending $50 on samples to confirm the toy was good quality. She also used a sourcing agent for $300 who inspected the factory prior to committing to her order. Her first order sold out in one month! She sold her pet toys on Etsy, and made a reasonable profit! Sarah went from 1 unit to 2,000 & got a 10% discount for guaranteed orders. It generated $50,000 per year in income on that line alone. What was the secret? Sarah went for quality over price. The supplier was slightly higher in cost, which was irrelevant to her. The supplier had fantastic reviews. Sarah had a friendly dialogue through WeChat, with supplier updates, and it became easier to get faster feedback. Lesson to consider? Start small and confirm everything & strengthen ties. Slow and steady wins the race. For Sarah, she used patience and due diligence to transform her side hustle into a respectable source of income.

Now for a flop. Mike was a retailer that ordered 5,000 phone cases without samples or contracts, just a “great deal“ he saw online, with a price quotation at half the going price. He jumped in without checking credentials. The shipment arrived, and 70% of the shipment had defects, i.e. warped plastic, and peeling logos. Because there was no paper trail, he had no legal recourse, and ate $8,000. After the payment cleared the supplier ghosted him. Mike was then forced to source locally at three times the price to save face with the clients, and lost another $5,000. Lesson learned? Never skip due diligence! Inspections and contracts are NOT optional; they are your safety net. Mike ignored warning signs, like poor communication, and lost. I’ve seen others fall into the same trap; cheap deals often come with expensive problems. Don’t let excitement heal your judgment – inspect, inspect, inspect.

I have my own story, and it is a mixed bag. In my early days in sourcing, I was sourcing kitchen gadgets for an online store. I found a supplier from the Canton Fair, liked the sample, and placed an order for 1,000 units. After confirming the order, I thought it was silly to inspect mid-production since I was already satisfied with the sample. The last shipment arrived with an uneven finish—the coating was flaking off on 50% of the products. I sold 600 at full price but had to sell the other 400 at a huge discount to get rid of them. I lost $2,000 in profit, but I had now learned a hard lesson: always insist on inspections at every stage. You are never too busy to inspect, period. I could have hired a local inspector for $300, which would have saved me the loss. It was painful but it was a learning experience. Since that incident, I do not cut back on quality control inspections, even on small runs. At some point, you are going to experience a failure as a result of a reckless decision – do your best to minimize the damage by developing safeguards. My mistake was not fatal, but it was painful enough for me to make permanent changes to my approach.

So, what can these lessons teach us? First, always test before you invest. Doing small orders, as well as, requesting samples provide the opportunity to discover deficiencies early. Sarah’s patience at first paid off, while Mike’s “leap of faith” got him burned. Second, legal protections and inspections are not additional options, they are part of the structure. I lost money that I didn’t need to lose simply because I neglected to follow an inspection protocol. Finally, relationships matter and take time to build. When Sarah formed an bond with her supplier, she received great benefits. When Mike disregarded doing due diligence on his supplier, he ended ed up with burnt fingers. Sourcing is about building exceptional relationships, not just transactional events. Good or bad, I learn from every deal that I participate in, and so will you if you take it seriously. So keep a journal of lessons learned and every order will contribute to that learning! But now let’s look into the future! What does sourcing from China even look like moving forward? The future has many changes that you will want to be aware of.

The Future of Sourcing from China: What Comes After?

China’s manufacturing scene isn’t stagnant, it’s rapidly changing. So what does that mean for sourcing? Trends have shifted many times over my career; it’s exciting, and a little unsettling. Let’s take a peek into the crystal ball to see what this may mean for business owners like you. Try to keep an open mind; being adaptable is critical because what works today may need an adjustment tomorrow. China’s role as the “factory of the world” is changing and keeping ahead means knowing what is coming.